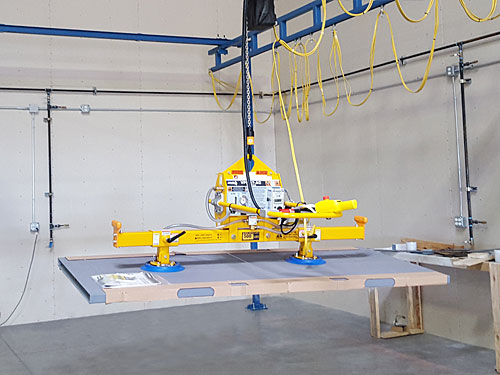

Vacuum lifters with a lifting capacity of 20.000 kg can be used to handle heavy sheet metals. Safety is of paramount importance when handling heavy loads. The proven traverse system and intelligent arrangement of suction plate and individual components are designed to ensure maximum stability. They prevent product deformation during transportation. Operators are alerted via visual and audible warnings about possible problems. A vacuum accumulator is installed in the hot-dipped galvanized main traverse and reliably maintains, for example. In the main traverse of hot-dipped galvanized main traverse, a vacuum accumulator ensures that the vacuum is maintained for a longer time and allows the transport load to be safely lower in the event of an emergency.

ASE Systems provides a wide range of standard and customized equipment, as well as material handling solutions, for any application found in commercial and industrial environments. There are three types of vacuum lifters: electric, mechanical and air-powered. They can lift up to 60,000 lbs (26.600 kg), or more, depending on your requirements. Our reliable line of vacuum lifting tools from ASE Systems will help you increase productivity and decrease worker injuries.